Beryllium Copper

UWE, Inc., is an industry leader in photo etching and heat treating beryllium copper (BeCu), an alloy with a wide range of industrial uses. Many organizations have come to rely on us for chemical etching beryllium copper materials. Because our etching process dissolves unwanted material without the need for grinding or machining, we are able to work with beryllium copper in ways other methods of metal removal cannot duplicate.

About Beryllium Copper

Beryllium copper is a copper alloy that contains 0.5% to 3% beryllium, and in some cases other elements as well. It also goes by the names beryllium bronze, copper beryllium, and spring copper.

BeCu has high thermal and electrical conductivity, high strength (especially if subjected to heat treatment), and strong corrosion resistance. Due to the advantageous mechanical properties of this alloy—it is highly machinable and ductile—beryllium copper is widely utilized in the electronics and aerospace industries sector to make a broad array of parts.

Beryllium copper can be found in load cells, transformers, spring wire, EMI/RFI shielding, landing gears, washers, leadframes, and electronic circuits, among many other applications.

Alloy 25/172 is the most common beryllium copper available. When heat treated, Alloy 25/172 can attain ultimate tensile strength higher than 200 ksi and its hardness approaches Rockwell C45.

Beryllium copper properties are determined by composition as well as cold working and age hardening:

- Beryllium copper in the annealed condition is designated by a letter “A”—for example, Alloy 25A.

- The suffix letter “H” shows the alloy that has been hardened by cold working such as 1/2H.

- The suffix letter “T” following an “A” or “H” shows the alloy has been given a standard heat treatment such as 1/2HT.

- Beryllium copper with an “M” suffix has been processed at the Mill to change its temper.

It is important to keep in mind that to obtain ½ hard temper, the material is work-hardened. Heat treating annealed material will yield AT temper material. Heat treating material designated as ½ hard will yield 1/2HT temper.

Uses of Beryllium Copper

The unique properties of beryllium copper alloys make them suitable for creating a range of materials, such as:

- Non-sparking tools and materials – Beryllium copper does not produce sparks upon impact with other metals.

- Non-magnetic parts – These can be helpful in a wide variety of applications.

- Elastic parts – Beryllium copper’s high elastic limit is valuable in the manufacture of springs and similar parts.

- Plastic injection molds – BeCu quickly removes heat from plastic materials and will not transfer toxins to the finished product.

Common Beryllium Copper Products

- Springs

- Clips

- Washers

- Switches

- Threaded fasteners

- Die inserts

- Guide rails

- Bearing cages

- Sliding bearings

- Connector contacts

- Instrument diaphragms

- Surgical instruments

Keep in mind that this is far from a complete listing. BeCu products are in fact extremely varied.

Applications/Industries Served by Beryllium Copper

Many industries benefit from beryllium copper’s mechanical properties, such as its high ductility, and the various other advantages associated with this alloy. For instance, the petroleum sector depends on beryllium copper to produce reliable workplace tools that will not generate sparks on impact (which can easily trigger fires and explosions in these environments).

Other industries that commonly use this alloy in its manufacturing and production processes include:

- Aerospace

- Automotive

- Consumer electronics

- Telecommunications

- Rail transport

However, beryllium copper parts can be found in nearly every business sector, either as components in manufactured products or as tools and accessories that support production processes.

Advantages of Chemical Etching Beryllium Copper

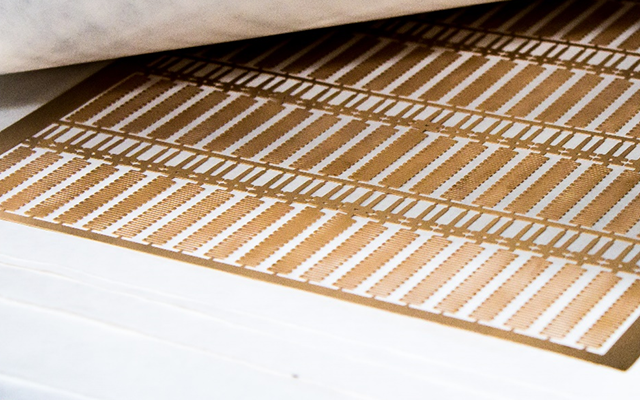

Photo etching beryllium copper provides several production benefits that cannot be matched by processes such as stamping or laser cutting. For instance, microelectronics parts that include beryllium copper demand high-precision craftsmanship that will not deform the surface of the material.

By chemical etching beryllium copper components, we can create highly intricate designs, even on very thin or tiny surfaces, without the burrs associated with lasers and water jetting or the mechanical stresses associated with stamping. Furthermore, photo etching beryllium copper does not require expensive tooling, as it is a CAD-driven etching process.

Heat Treating Beryllium Copper

Heat treating can substantially increase the strength and hardness of beryllium copper. Although all copper alloys can be cold worked to strengthen them, beryllium copper is unique among these alloys in its responsiveness to heat treating as a method of achieving this result.

Beryllium copper heat treatment consists of two steps:

- Solution annealing – This step involves heating the material to make it softer and more ductile. It is also required to prepare the material for precipitation hardening.

- Precipitation or age hardening – This step exposes the material to lower temperatures (relative to the solution annealing phase) to form precipitates, which markedly increase the strength of the material.

Please contact us for more information on our current beryllium copper prices.

Why UWE?

To enjoy the advantages of beryllium copper parts, your company needs an experienced partner like United Western Enterprises, Inc. As an expert in photo etching processes, we handle everything from springs to encoder disks.

The list of clients that currently use products chemically etched in our facility includes companies in the automotive, aerospace, military, medical, and electronics industries. We are an AS 9100D / ISO 9001:2015 Certified Company. Be sure to contact us to learn more about chemical etching beryllium copper at UWE, Inc.