RFI and EMI Shielding

In a society increasingly reliant on a wide array of electronic devices, radio frequency and electromagnetic shielding play a vital role in keeping this equipment in sound working condition and ensuring compliance with regulations enforced by the military and the Federal Communications Commission (FCC). United Western Enterprises is highly experienced in developing, manufacturing, and improving custom RFI and EMI shielding. Shields can be manufactured exactly to your desired specifications.

One-piece shielding, shielding with peel-away tops, or two-piece shields consisting of a “fence and cover” combination are typical designs for shielding. We are willing to work with you in the development of your custom application.

Where Does EMI and RFI Come From?

Electromagnetic interference (EMI) is a disruption of signals between electronic components. Similarly, RFI (Radio Frequency Interference) is a disruption of radio signals. EMI can interrupt the quality of a cell phone call, radio station, or signals passing through circuit boards.

Sources of EMI come from man-made devices and the environment. Lightning, solar magnetic storms, and Earth’s magnetic field can generate interference, while computer circuits, as well as devices such as brush motors and arc welders, can generate their own interference. Power quality issues can also cause EMI. Furthermore, a blackout, brownout, power line fault, voltage spike or sag, or electrical noise on a main power line can cause electromagnetic interference.

With cellphones in the hands of just about every citizen, overcrowded airwaves sometimes lead to disruptions of wireless signals. In short, wireless devices can interfere with one another. Other applications in which electronic devices may be affected by electromagnetic fields include:

- Medical equipment: Electromagnetic and radio frequency interference (RFI) can disrupt X-ray machines and patient telemetry equipment and life-saving systems such as surgical room electronics, ventilators, and infusion pumps.

- Railroad/mass transit systems: Train control and propulsion systems, third rail shoes, and high-voltage contact switching systems may produce EMI that affects sensitive electronics. Signaling and control systems can as well, and they require shielding materials to function properly.

- Military assets/infrastructure: High-power microwave weapons, electromagnetic pulse cannons, and high-altitude nuclear electromagnetic pulse weapons—collectively assets of electronic warfare—need to be protected from EMI.

The solution is to surround electronic components and cables with EMI shielding. Metal screens, sheets, or mesh may be used to surround cables and other sensitive parts. These shields mostly resemble flat sheets that prevent electrical or magnetic fields from elsewhere interfering with the device, or from EMI interference being emitted by that device.

Types of EMI-Shielding Products We Have Experience With

With decades of experience in the field of photochemical etching behind us, we have wide-ranging insight into the characteristics and uses of various EMI-shielding products.

EMI shields are found in many shapes and sizes and may be produced out of nickel silver, tin-plated steel, stainless steel, or Mu-metal; they can also be brass, bare or plated. In order to keep equipment in working condition and to comply with military and Federal Communications Commission regulations, the following types of electromagnetic shielding may be used:

Gaskets

Formed metal sheets can be produced in various sizes, shapes, and configurations to fit electronic enclosures. Metal screens used as EMI shields are now typically flexible to prevent deformation that can allow electronic circuits to leak and receive interference.

Board Level Shielding

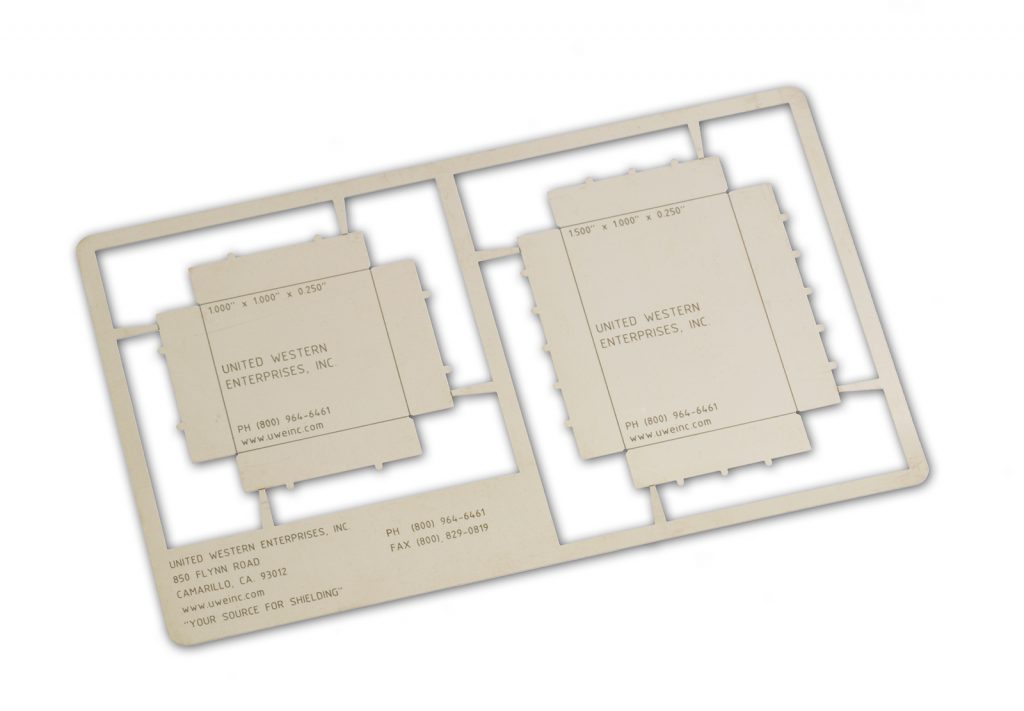

Printed circuit boards, small and sensitive, are found in just about everything. EMI shields safely isolate board level components and reduce the incidence of crosstalk. Custom one- and two-piece surface-mount shields are available through United Western Enterprises.

EMI Shielding Materials

Our shielding enclosures and related products are made from various materials:

- Brass, bare or plated

- Tin plated steel

- Nickel silver

- Mu-metal

- Stainless steel

- Aluminum

Typical Shielding Applications

Our EMI- and RFI-shielding products can be found in many different applications, such as the following:

Electronic equipment

Electromagnetic and radio frequency interference can erase data and/or cause irreparable damage in this type of equipment if it is not shielded properly.

Medical equipment

Hospitals and other medical facilities have a high density of equipment that can be harmed when exposed to EMI and RFI, such as monitoring devices.

Military and aerospace

Our shielding products are used on many military-based units in conformity with the unique demands of the modern aerospace industry.

Automotive components

EMI shielding is increasingly important in the automotive sector to ensure that electronic components in a vehicle function correctly without interfering with one another.

Our EMI Shielding Products

Since conductive gaskets and other EMI shielding materials are often so small, cutting and stamping are not effective ways to make them. United Western Enterprises uses a process called photo etching that produces no stress on the material. Components can be designed to exact specifications, yielding parts that are thin, fit exactly into the application, and retain the material’s full strength.

We can provide forming services to ensure each part suits your electronic equipment. Product prototypes can be created quickly and inexpensively. In-house welding and soldering services are also available. From power lines and cables to small grounded wires, to capacitors and other electronic components in circuits, the need to minimize EMI noise can be addressed with EMI shielding.

Custom RFI and EMI Shielding

Our custom EMI-shielding solutions ensure that you can purchase materials that conform 100% to your specifications. They can be etched as flat pieces with or without etched bend lines to ease forming at your facility, or we can shape them at our in-house forming department. Part numbers, logos, or other identifications can be included on your shields as well to bring the shielding further into accordance with your business needs.

Added Processes

United Western Enterprises also provides other services to help customers enjoy the full spectrum of benefits associated with high-quality EMI/RFI shielding:

- In-house forming in our own dedicated department.

- Welding seams closed—we do laser welding in-house.

- Soldering open seams shut.

- Plating, especially to brass and steel parts, aids in soldering to boards and protecting the base material from oxidation.

To learn more about our electromagnetic shielding parts, materials, and custom solutions, contact us online or by email or phone.