4 Benefits of Using Photo Etching for Manufacturing Thin Metal Parts in the Auto Industry

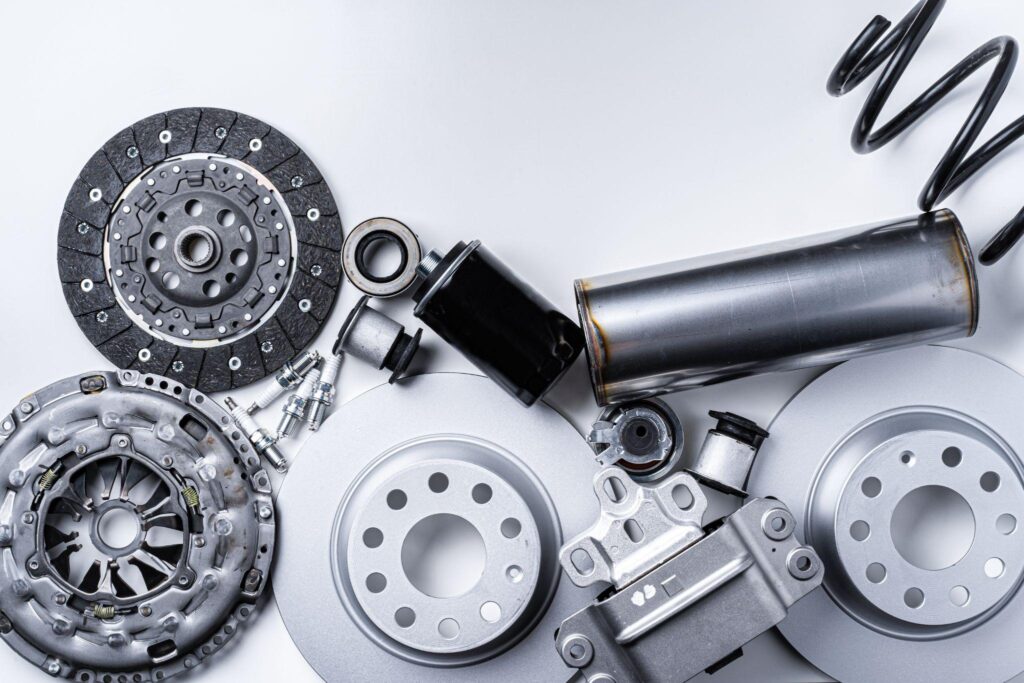

Automobiles are highly complex machines that contain a large number of interconnected components, and as any car owner knows, there’s a lot that can go wrong with these vehicles. A failure in nearly any area of the automobile—engine, transmission, suspension, brakes, etc.—can significantly impair the vehicle’s functionality or even prevent it from running at all.

The manufacturing of automobiles, then, calls for a high degree of precise craftsmanship, applied across a broad spectrum of parts and materials. This includes a lot of very thin parts that somehow must be molded properly without harming their structural integrity. Thin metal parts can be found in multiple areas of an automobile, such as:

- Suspension – Coil springs and leaf springs play an important role in supporting the suspension system and ensuring a smooth, comfortable driving experience.

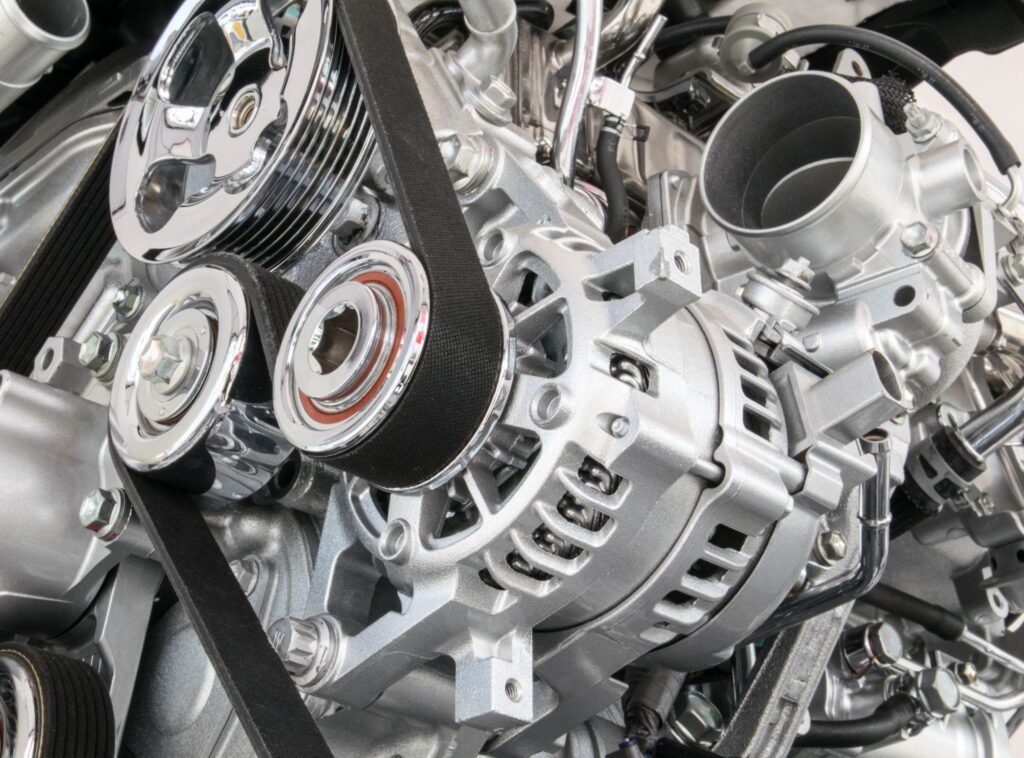

- Engine – This essential auto device contains a variety of thin parts, such as piston rings and valve springs, that enable sound engine performance.

- Fuel injection system – Several thin metal parts, including injector nozzles, help to circulate fuel in an efficient manner.

- Electrical system – Connectors and EMI/RFI shields are among the thin components that promote the healthy functioning of the car’s electrical system.

What auto manufacturers need is a production process that can manage a variety of parts and components while retaining a high level of quality consistency across the entire production run. Ideally, it should be possible to attain these benefits in a reasonably cost-effective way.

Photochemical etching (sometimes called photo etching or chemical milling) has emerged as a flexible, highly productive process of manufacturing thin metal parts that conform to the strict performance requirements of the automotive industry. It uses etchants such as ferric chloride to dissolve precisely demarcated areas on metals selectively covered by a photoresist. The result of this process is a component that complies exactly to manufacturer’s specifications.

For auto manufacturers, an experienced third-party photo etching company can provide a number of cost-saving production benefits that, in an increasingly tight economy, should not be overlooked. Let’s take a closer look at four key advantages provided by photo etching services.

Suitable for Delicate Materials

Several widely used fabrication methods inflict mechanical or thermal stress on the materials being processed. For example, laser cutting, which uses a highly concentrated beam of light to slice through metal, tends to leave behind slags or burrs due to the use of concentrated heat. These can be removed afterward, but the process increases manufacturing times; and in the case of very thin or delicate metals, the damage from thermal stress can be irreparable. Sometimes this is an issue that develops only over time: The cutting machine initially produces a very clean surface, but mechanical strain from overuse gradually leads to a greater incidence of burrs and similar defects.

Mechanical stamping is another common manufacturing technique that can cause problems with the treatment of thin metal parts. Because stamping uses a die and punch to form materials, the process can inflict distortions that damage thin metals and render them unusable.

By contrast, photochemical etching evades these issues by shaping metals with etchants, not thermal or mechanical stress. That’s why photo etching is useful for delicate materials that might be harmed by other processes. And by leaving behind a burr-free surface, etching minimizes overall production times (and costs).

Simple Pre-Production Process

Many fabrication methods rely on specialized tooling that must be designed and pieced together before the actual manufacturing of the part or component can proceed. This costs money; and if revisions are needed to the tooling—which is not at all uncommon—then these pre-production expenses will rise markedly. With photochemical etching, though, the pre-production process is much easier to manage.

Prior to the fabrication of the part or component, the photo etching company will create a computer-aided design (CAD) file that allows the technician to produce a durable photoresist. The photoresist is then placed onto the part and selectively hardened via exposure to ultraviolet (UV) light. This enables the etching process to dissolve unneeded portions of the material and shape the part according to the precise pattern required by the manufacturer.

There is no tooling hardware involved in this process—everything is designed by computer. Similarly, design revisions can be easily performed by modifying the CAD file, as opposed to needing to create brand-new tooling. Compared with other methods, the pre-production process is not only simpler, it can more easily accommodate rush orders that require fast turnarounds.

Mass Production Capability

Whether you need a single prototype or thousands of identical parts, photochemical etching provides the best pathway to reaching your production goals. Etching achieves its effects by immersing materials in a corrosive bath, and when necessary it’s easy to adjust the number of parts being fabricated at any given time.

This process offers an extremely high level of repeatability in parts production, as the etchant does not “wear out” in the same way a mechanical fabrication device might. Etching is also quite fast; unlike a laser or similar device, a chemical etchant can work on all areas of a part simultaneously. Therefore, etching provides a reliable method to produce many high-quality components in a short time frame—an obvious advantage for auto manufacturers that require an enormous number of thin metal parts.

Design Flexibility

Thin metal parts installed in automobiles come in a broad array of shapes and sizes. They’re also made of various types of metals and alloys, including but not limited to stainless steel, aluminum, and copper. Finding a single production process that can handle such a wide diversity of materials and design requirements might seem to be a futile endeavor, but with photochemical etching this is well within the realm of possibility.

A photo etching company can expertly utilize one or more of a number of available etchants, such as ferric chloride, nitric acid, and hydrochloric acid, to effectively treat the particular type of metal being processed. Etchants can create extremely complex (computer-aided) designs as well. Chemicals naturally work their way around the photoresist, which can assume virtually any configuration that can be designed by CAD.

Contact UWE for the Best Photo Etching Services in the U.S.

Auto manufacturers stand to gain a number of vital production benefits by partnering with a company that can provide advanced photo etching services. United Western Enterprises is a highly respected photo etching company with decades of experience serving the automotive sector as well as the medical, aerospace, and electronics industries. Based in Camarillo, CA, UWE, Inc., carries out its etching operations in an AS 9100D / ISO 9001:2015 Certified facility. Call us at (800) 964-6461 to learn more about the best photo etching services around today.