Industries Served | Photochemical Etching

The photochemical etching process is used by a variety of industries to create parts and components. Photochemical etching can be used on a large-scale or small-scale basis, as well as for a one-up prototype.

Medical Industry

The precision and high tolerances that are necessary for parts and components used in the medical industry are well-suited for photochemical etching. There is a wide range of medical devices and equipment that include photochemical etched parts and components. You can find these parts and components in:

- Orthodontic Appliances

- Dental Appliances

- Sensor Elements in Medical Monitoring Devices

- Filters

- Sleeves

- Medical Instruments

- Medical Blades

- Veterinary Instruments

- MRI Litz Coils and Field Alignment Parts and Components

- Medical Incision Closures

- Lead Frames

- Battery Contacts

- EMI/RF Shielding

- Anodes

- Cathodes

- Contact/Retention Springs

- Board Level Shielding

From hearing aids to surgical instruments, photochemical etching provides the best biocompatible and precise parts and components.

Aerospace and Military Defense Industry

The aerospace and military defense industry requires high quality and precision parts and components that need to be reliable. To achieve this level of quality, photochemical etched parts and components are often the best solutions.

Photochemical etching is compatible with the high grade of materials required to produce parts and components, including titanium and aluminum. Creating parts and components using chemical etching uses non-contact methods. This eliminates distortions and heat stress to produce the high level of parts and components required.

In addition, parts and components can be miniaturized to precision details. Furthermore, highly complex parts and components can be created and produced without an increase in costs or production time.

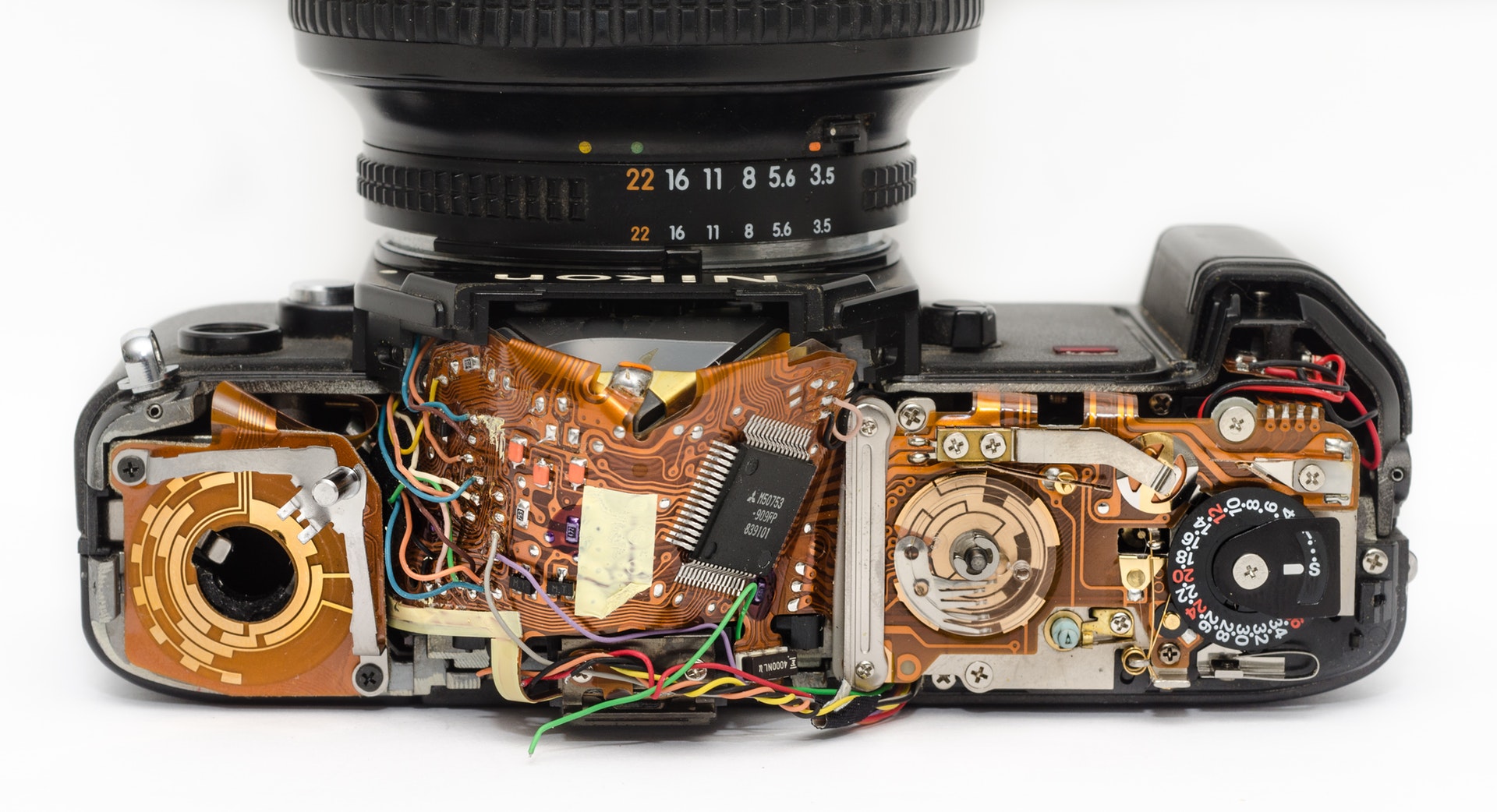

Electronics Industry

There are numerous electronics that rely upon photochemical etched parts and components, from lead frames to semiconductor cooling plates, springs, connectors, contact plates, and more. Each part and component can be created with any level of detail and complexity, as well as any size.

With more and more electronic parts and components becoming smaller and smaller, photochemical etching is an ideal solution for accuracy and precision. It will ensure parts and components are burr-free and distortion-free to achieve high-quality results. Plus, parts and components can be produced using various metals found in electronic devices.

Automotive Industry

Photochemical etching in the automotive industry produces a variety of parts and chemicals that require precise tolerances and dimensions. With automobiles becoming more complex and with a wide range of features and options, from infotainment systems to advanced safety features, these systems require accurate and reliable parts that will last and function when needed.

Jewelry and Watches Industry

There are several different types of jewelry and watches that utilize the precise parts and components produced using chemical etching processes. For instance, modern watches require customized thin metal parts that must be carefully crafted for precision movement.

Other processes would be too cumbersome to produce the level and quality of parts and components required. Aside from watches, chemical etching can be used to create custom jewelry pieces and incorporated into their design, like earrings, gemstone settings, and others.

Get Additional Assistance

For additional information about photochemical etching, the types of metal materials that can be used, to see how easy it is to produce the parts and components you require, and to request a free quote, please feel free to contact United Western Enterprises, Inc. at (800)964-6461 to speak with a representative today! We have been photo etching custom and thin metal parts and components since 1969!