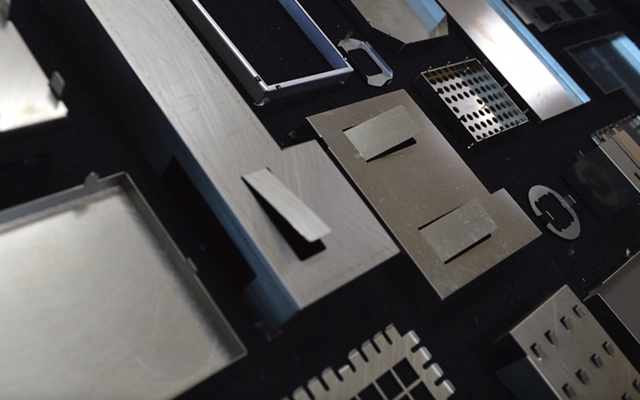

Photo & Chemical Etching | Nickel

Nickel alloys are often used in electrical applications. Some nickel alloys possess unique properties that enable them to be employed successfully across various industries.

United Western Enterprises provides cost-effective nickel-etching services to our customers. We are capable of chemical etching nickel and many of its alloys, such as:

- Nickel alloy 200 and 201

- HyMu and other Mu metals

- Alloy 42

- Alloy 48 and 49

- Inconel 600 series

- Monel

About Nickel

Nickel is a highly versatile metal that is prized for its ability to alloy with many other metals, and for that reason it is widely used in the industrial sector. It is often deployed as a protective coating in devices and equipment with delicate parts or weaker metal surfaces. In its pure form, nickel can be found in various kinds of electronics and aeronautical gear; in alloy form, its range of applications is substantially broader. The notable properties of nickel and its alloys include the following:

Heat resistant – Nickel holds up well in temperatures up to 500°C. Nickel-chromium and nickel-chromium-iron alloys are especially durable, with strong anti-oxidation properties, in very high temperatures.

Corrosion resistant – Nickel is strongly resistant to freshwater, saltwater, and organic acids. Alloy 825 (a nickel-iron-chromium alloy, with copper, molybdenum, and titanium) offers exceptional resistance to sulfuric acid and many other corrosive substances. Nickel can be electroplated onto other metals with ease to provide a high level of protection against corrosion.

Electro resistant – Pure nickel’s naturally high resistance to electricity makes it valuable in applications that require effective shielding against electromagnetic interference, among other uses.

Strongly ferromagnetic – Certain nickel-iron alloys have ferromagnetic properties that allow them to be used in transformers, inductors, and similar devices.

Low thermal expansion – Nickel-iron alloys (particularly Invar) are suitable for devices that demand very low thermal expansion.

Advantages of Chemical Etching Nickel

Photo etching nickel can generate a number of attractive design features that are difficult to achieve with alternative metal etching methods. For example, chemically etched nickel will not contain the kinds of burrs and thermal stresses that routinely result from laser cutting techniques.

However, the chemical etching process must take into account the tendency of nickel to form an oxide layer that resists etching. The engineering team at United Western Enterprises understands the unique challenges posed by photo etching nickel and strives to deliver cost-effective solutions to our customers.

UWE, Inc., for Your Nickel-Etching Needs

Since 1969, United Western Enterprises has supplied a wide variety of photo etching services to the aerospace, automotive, medical, and electronics sectors. Whether your organization requires help with a high-volume production run or just a few parts, you can rely on UWE, Inc., and our many years of photo-tooling expertise. Our value added options give you additional choices to form parts according to your precise specifications. We are a AS 9100D / ISO 9001:2015 Certified Company. Feel free to contact us for more information on our chemical etching process.