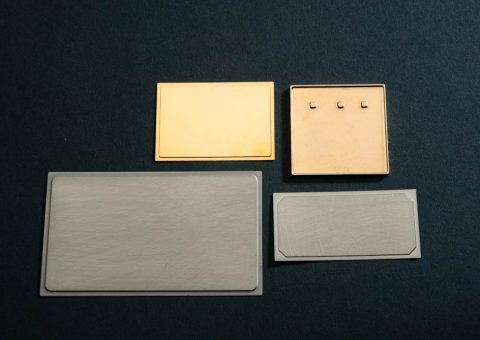

Photochemical Etched Covers & Lids

Covers or step lids can be a challenge. They need to be precise and fit tightly in their mating enclosure. They also need to stay flat so they can be welded easily. Chemical etching can be the answer to these tough problems. Machining, grinding, or stamping can add stress to any part, particularly when the part has a less than full thickness flange around its edge. By dissolving any unwanted material, photo chemical etching can produce the step lids that fit correctly and stay flat.

Photo etched covers are precisely sized, have no unwanted material, and fit perfectly every time. We can create many types of covers and lids that need to fit micro-electronics, optical, fiber optic, RF, and many other applications. These are just a few examples of applications that regularly demand high-precision components in order to function according to design expectations.

Typically, lids are made out of Kovar because of its low expansion characteristics, but they can be made out of other less expensive materials as well. We can take care of any plating your parts need. Usually, the plating will be nickel, tin, or gold, but we produce covers and lids according to your specifications and can create chemically etched step lids, for example, out of:

- Spring SteelAdvantagesHigh yield strength: Spring steel can withstand significant bending or twisting forces without permanent deformation.

Excellent elasticity: It can return to its original shape after deformation, making it ideal for spring applications.

Cost-effective: Generally cheaper than many other high-performance alloys.Disadvantages

Corrosion susceptibility: Unlike stainless steel, spring steel is more prone to rusting when exposed to moisture.

Limited temperature resistance: Prolonged exposure to high temperatures can alter its mechanical properties. - Stainless Steel

AdvantagesCorrosion resistance: Stainless steel has a chromium-rich oxide surface layer that protects it from rust and corrosion.

Durability: Resistant to both low and high temperatures, and maintains its strength in various conditions.

Hygienic: Non-porous nature makes it the material of choice for food and beverage, medical, and pharmaceutical industries.Disadvantages

Cost: Generally more expensive than regular carbon steel.

Not the best conductor: Stainless steel’s conductivity is lower compared to metals like copper. - Phosphor Bronze

Advantages

Good conductivity: Excellent for electrical contacts and connectors.

Corrosion resistance: Especially to saline environments, making it suitable for marine applications.

Good fatigue resistance: Suitable for springs and other cyclic load applications.Disadvantages

Cost: Generally more expensive than some other copper alloys.

Not as strong as steel: Lower tensile strength compared to steels.

- Beryllium Copper

Advantages

High conductivity: Suitable for electrical applications.

Non-sparking and non-magnetic: Ideal for use in explosive or magnetic environments.

Excellent mechanical properties: Can be hardened to achieve strengths comparable to some steels.Disadvantages

Cost: One of the more expensive copper alloys.

Health concerns: Dust or fumes from machining can be toxic if inhaled. Proper precautions are necessary during processing. - Copper Alloys

Advantages

Good conductivity: Efficiently conduct electricity and heat.

Malleability: Can be easily shaped and formed.

Corrosion resistance: Especially to atmospheric conditions.Disadvantages

Strength: Generally, not as strong as steels.

Prone to galvanic corrosion: When in contact with other metals in a moist environment. - Nickel/Nickel Alloys

Advantages

High temperature stability: Retains its properties under extreme temperatures.

Corrosion resistance: Especially to oxidizing agents.

Magnetic properties: Certain nickel alloys can be used in magnetic applications.Disadvantages:

Cost: Nickel and its alloys can be quite expensive.

Weight: Heavier compared to materials like aluminum, affecting its use in weight-sensitive applications.

Photo etching gives us the ability to create parts for nearly any application.

Lead times are shorter than with traditional processes and tooling.

The cost of setting up the tooling and producing parts is much lower as well. We can also produce many parts in one production run, without having to machine each one separately, which is costly and time-consuming.

Often, many parts can be etched out of a single sheet of metal. All the attributes of chemical etching enable us to accommodate applications, including:

- Electronic equipment: Micro-electronics, optical windows, circuits, RF components, seals, battery compartments, and enclosures.

- Medical equipment: Various types of medical devices, electronics, instruments, and components requiring high precision.

- Military and aerospace: Heavy-duty, sensitive electronics used in extreme environments ranging from the battlefield to the vacuum of space.

As with any chemically etched part, the tooling can be generated quickly and inexpensively. If any adjustments need to be made to the part on future orders, adjusting the tooling is fast and easy. Contact us by phone or email to discuss your application, ask any questions, or make changes to your order. Feel free to request a quote online today regarding photo etched covers and lids.