The Benefits of Photo Etching

Photo chemical etching (PCE) is a subtractive manufacturing process that involves the use of photo-reactive resist to fabricate precision metal parts. It is also known as photo chemical machining (PCM), photo etching, and chem etching—all these terms refer to the same process.

Photo etching is similar to other printing processes. It images part dimensions onto photoresist coated metal, which is then developed to wash away specified portions of the photoresist. After this, the metal part is submerged in an etchant that selectively removes the exposed areas of metal not protected by the remaining photoresist.

This process produces intricate parts with tolerances (as low as ± .01 mm) that would be otherwise unachievable with processing methods such as laser cutting, water-jet cutting, stamping, punching, or die-cutting.

Advantages of the Photo Etching Process

Chemical etching offers many advantages over other milling techniques that may not be as accurate or economical. It:

- Doesn’t introduce any sources of mechanical stress: With chem etching, each part maintains the mechanical properties of the customer’s selected metal (or metal alloy).

- Dissolves the unwanted metal via chemical reaction: Burring, shearing deformation, and ablative deformation typically associated with other machining processes are avoidable.

- Improves precision: Chemical etching can be used with materials as thin as 0.0003 inches. Holes can be as small as 0.004 inches, while edge dimensions can be within ±10% of a part’s thickness.

- Allows for high part quantities: Large volumes of parts can be put into production on short notice, which allows a higher degree of flexibility.

- Supports greater part complexity: The photo chemical etching process can yield metal components with complex multi-dimensional characteristics; it can even create score lines so parts can be folded.

- Lowers production costs: Tooling adaptations are easy to make, and a design change may cost only a couple hundred dollars, reducing the cost overhead for metal part prototyping and full production.

Although chem etching isn’t always the best option for every application, its various advantages have made it the preferred choice for manufacturers in a wide range of industries.

Cost Benefits

Etching metal is more cost-effective than other machining processes because it allows for more complex designs with intricate features. Increasing design complexity often doesn’t result in increased production costs. The faster processing time of chem etching reduces costs as well. An etch rate of 0.0005 to 0.001 inches per minute is possible, so many parts can be completed within a day. The process also eliminates rework, so project costs are centered only on the initial process.

The ease and speed of designing tools also lower costs. For example, building stamping tools can take weeks and cost thousands of dollars. Maintaining them and addressing wear and tear can be costly as well. That partly explains why production with photo chemical etching can be much less costly than stamping or punching.

With metal etching, part quality is improved as well, due to the absence of mechanical and thermal stresses that can cause distortions in the material. This makes your products more valuable and cuts out post-production steps such as deburring, which is often costly and time-consuming. Chemical etching also supports more affordable mass production (as many as millions of pieces can be produced economically). Given the speed and accuracy of the process, customers can complete prototypes and get products to market faster, increasing profits.

Metals and Common Parts

United Western Enterprises, Inc., works with many metal alloys. These include several types of versatile, lightweight aluminum alloys. We also work with the purest copper alloys, as well as phosphor bronze, brass, and nickel silver (often used for RF shielding, but less costly than nickel plating with the same luster). Other materials include beryllium copper, nickel and nickel alloys, and a range of common stainless steel alloys suited for various parts and environments.

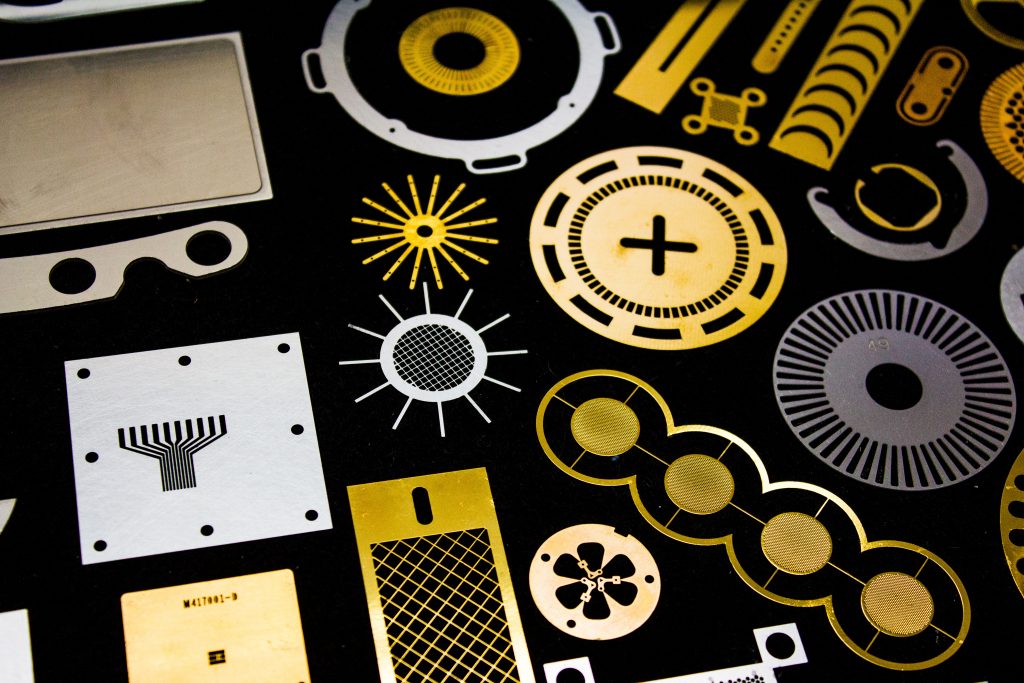

Many everyday parts can be produced with photo etching. These include circuit board components and electronic devices such as image sensors, attenuators, and parts for digital cameras and waveform samplers. EMI and RFI shielding, metal shims, apertures, encoder discs, springs, and contacts with different gauge metals can be made. Chemical etching works for everything from battery components and heat sinks to the production of medical imaging equipment, radar systems, and telescopes.

Order Precision Metal Parts Today

Photo etching is an efficient, low-cost method of producing parts with tight tolerances and minimal imperfections. At United Western Enterprises, Inc., our photo etching expertise and commitment to serving our customers’ individual needs means you can get precisely manufactured parts in any quantity, with low turnaround times. We’ve been in business since 1969, and our decades of industry experience make us the ideal partner for your next manufacturing order.

To learn more about our chem etching services, call (866) 578-3805, email sales@uweinc.com, or request your quote online.