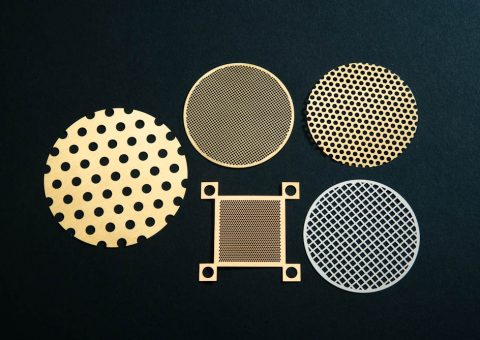

Perforated Metal Mesh Screens & Chemical Etched Screens

Photo etched screens can have extremely precise, intricate features, thanks to our state-of-the-art chemical etching process. Our etching process allows us to create metal screens with very fine webs and holes. These have a high degree of dimensional stability, so they stand up to stress during etching, handling, and use in demanding applications, including:

- Electronic equipment: RFI filters, particle filters, PCB shielding, speaker grilles, and water filtration equipment.

- Medical equipment: Filters, sensors, monitoring devices, surgical needle threaders, and medical implants.

- Military and aerospace: Fuel and hydraulic system filters, cabin air quality systems, and noise reduction components.

An etched screen may also be used in food-grade and clean room applications. In fact, photo etched screens are suited for the most sensitive technological requirements because they are extremely flexible and versatile.

Why Is Greater Material Integrity So Important?

Photo chemical etching is so precise it can be used in applications where the slightest mistake can have devastating consequences. This is no truer than in the medical industry. Chemical etching can be used to create small chemical etched screens for filters and components for medical implants and instruments. Defects in any of these can lead to malfunctions in testing equipment, malfunctions in implanted devices such as pacemakers, and potential harm to patients.

Metal screens, grids, filters, meshes, microfilters, grilles, and other components are small and often go unseen, but their quality has a profound impact on how complex equipment works. Just a small defect in a lighting diffuser can reduce light quality. A defective filter can cause issues with liquid and gas transfer in an industrial system.

Why Use Photo Etching?

With photo chemical etching, screens can be produced in various shapes. Hole openings are consistent to ensure each screen supports exact equipment specifications. Woven screens can become stretched and distorted, but our metal-etching process ensures dimensional stability. In addition to being burr-free (which isn’t often the case with stamping), each screen is flat. There’s also no thermal stress or metal deformation, which can occur with laser cutting.

Chemical etching is easier and less expensive than other methods. When design changes are needed, it is less costly to adapt the tooling. There’s also no need to replace tooling, as there isn’t the wear and tear that mechanical manufacturing equipment undergoes. Production times are shorter as well, so large quantities of components can be delivered faster than with traditional manufacturing methods.

How Precise Is Chemical Etching?

Chemical etched screens can be produced in custom dimensions and tolerances. We can make filters, sieves, and other screens regardless of complexity, in one piece, without the distortion, stress, and degradation that can occur with punching. Pieces can be burr-free. Webs can be as small as 2/3 material thickness. If a customer orders a screen etched out of .010” thick material, the webs can be as small as .006” wide.

Our process can also make photo etched screens with small holes. The openings on the screen must be at least 20% larger than the material thickness. Therefore, on a .010” thick screen, the holes must be at least .012” in diameter. We can create holes down to .004 inches with edge dimensions within ±10% of the overall part’s thickness.

Whether you need a single piece or as many as you need, photo etching remains just as precise and reliable.

Why UWE?

United Western Enterprises, Inc. can produce photo etched brass mesh, etched roof screens, and screens made out of stainless steel, aluminum, copper, and a wide range of alloys. We’re also familiar with the demands of various industries, including medical, automotive, electronics, and aerospace and military defense. And, in addition to providing a wide range of metal and alloy choices, we can help make decisions on material type, design, and other factors that can improve your manufacturing and rapid prototyping efforts.

United Western Enterprises, Inc. can meet all your perforated metal mesh screen requirements. To learn more or receive a free consultation, call 800-964-6461 or contact us online.