Photochemical Etching / Photochemical Machining

June 2021

United Western Enterprises has been known as the industry leader in advanced photochemical etching or photochemical machining since 1969 making us one of the most experienced partners for businesses seeking complex custom metal parts. UWE works with customers spanning multiple industries with extremely complex requirements with tightly controlled requirements through every aspect of the photochemical etching process.

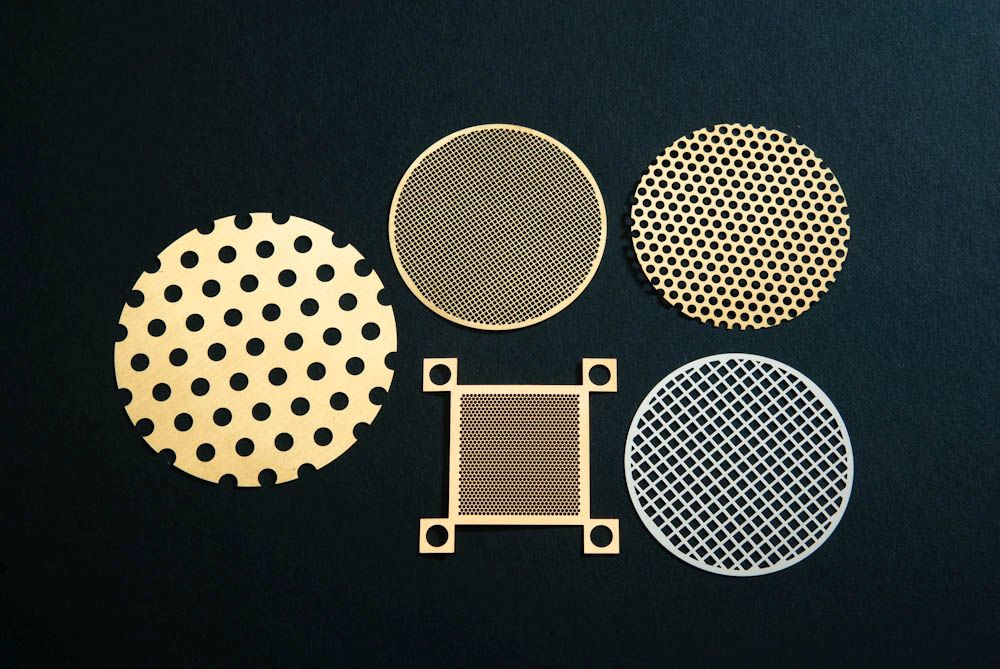

UWE’s photochemical etching / photochemical machining department utilizes a wide variety of etchants to produce a broad range of materials including five types of copper alloys, stainless steel, brass, aluminum alloys, silver, and nickel alloys. By design, UWE is able to create greater precision and finer geometry than most other photochemical machining / photochemical etching companies, as we excel far beyond the standard process.

What is Photochemical Etching / Photochemical Machining?

Photochemical etching, also known as photochemical machining, is a process that’s used to fabricate custom sheet metal components using etchants and a photoresist to corrosively machine away specific areas. Photochemical etching / photochemical machining as a process began in the 1960s as a ventricle of the printed circuit board industry. Organizations in the aerospace, medical, transportation, communications, space flight and military (to name a few) invest in photochemical etching / photochemical machining to acquire extremely complex parts that can be as thin as 1/100 the size of a human hair, and that have finely detailed specific components designed for accuracy and to help promote economically sound functionality.

Benefits of Photochemical Etching / Photochemical Machining

Photochemical etching, or photochemical machining, can offer good economical alternatives to producing components via punching, stamping, water jet cutting, laser cutting or wire electrical discharge machining. Photochemical etching’s tooling is inexpensive and offers quick production. As a result, the photochemical etching process is ideal for prototyping because it allows for simple, timely changes in mass production. Furthermore, photochemical machining continues to hold on to dimensional tolerances without creating sharp edges or burns.

Another benefit to utilizing photochemical etching is that engineers can make a part within hours upon receiving the design plans and drawings–another factor that adds to the quick turn-around time companies benefit from with photochemical machining.

Finally, photochemical machining can be performed on virtually any commercial alloy, metal or any hardened surface. It is only limited to materials with a thickness of 0.0005 to 0.080 in (0.013 to 2.032 mm). Some of the most commonly used metals used in photochemical etching / photochemical machining include copper, brass, aluminum, titanium, stainless steel, zinc, nickel, manganese, silver, inconel, and steel.

Chemical Etching with United Western Enterprises

Our customers often ask “What is chemical etching?” United Western Enterprises Inc. specializes in this precise chemical etching process, which allows metal parts to be produced to very close tolerances using computer aided design software, along with photography, chemistry, and metallurgy technologies. This cost-effective metal etching process allows us to quickly produce thin metal parts for many different applications.

What are the Steps in the Photochemical Etching Process?

Our photo etching process can be broken down into several steps:

Step 1. Phototool Design / CAD Design – Designs are submitted to us by customers, as a .DXF or .DWG file, or a drawing with which we create a phototool. Mailed or e-mailed, the file is converted into the working phototool our technicians use during every step in creating the final product. Adjustments and redesigns can be made quickly and cost-effectively by our experienced technicians.

Step 2. Metal Selection & Prep – Next, the metals to be used in the project are selected. Materials can include copper alloys, stainless steel, aluminum alloys, or nickel alloys. Prior to chemical etching, the metal is cut into sheets and cleaned. Any oil, grease, or oxidation is removed from the metal sheet to be processed.

Step 3. Photoresist Coating – A photosensitive material is then applied to the sheet. Sensitive to light, and resistant to acids, the photoresist is applied using a specialized coating machine in our facility.

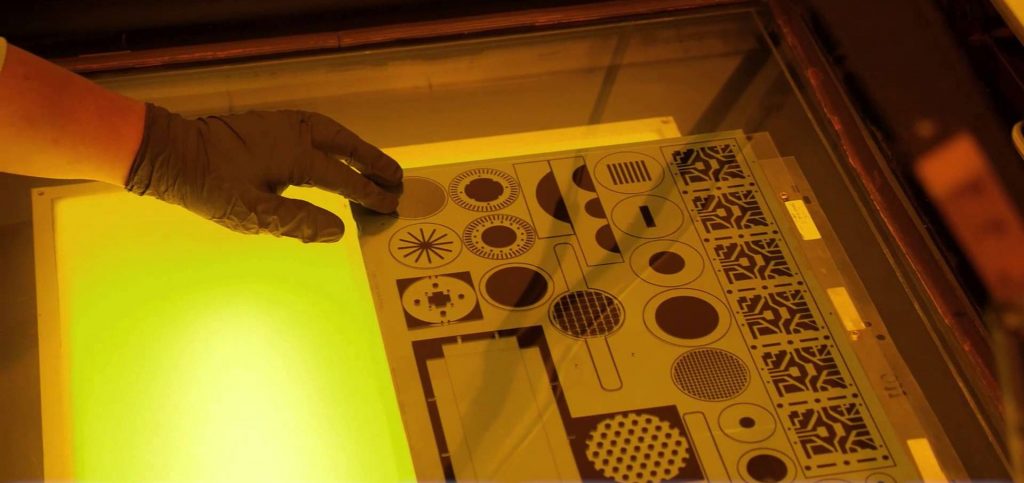

Step 4. UV Exposure – Once it is coated, the sheet is put into an exposure unit. It’s placed between two pieces of film, which have been designed based on the files submitted by the customer. The sheet is exposed to UV light on both sides. When light touches the resist it becomes hard or polymerized, and areas shaded from light remain soft.

Step 5. Development – During the development process, the soft resist is washed away, leaving behind the hard resist. Where the soft resist has been developed away, we are left with exposed material which will be dissolved away by the heated etchant. Areas with hardened resist will be protected from the etchant and become the parts desired.

Step 6. Chemical Etching – The etching process uses a range of etchants, depending on the base material used. Matching the appropriate chemicals ensures a more effective chemical machining process, in which etching metal is fast and effective. Metal burrs are not created with chemical etching.

Step 7. Photoresist Stripping – After etching the resist is completely removed, yielding the metal components the client has ordered and specified in the files they submitted.

Step 8. Final Inspection – Parts are then inspected, ensuring it meets proper dimensional specifications, is burr free, and has no other imperfections or defects. Our team also ensures all parts meet high quality standards when value added processes such as forming, laser welding, soldering, or plating are requested.

Contact UWE Inc. to Learn More About Photochemical Etching / Photochemical Machining

United Western Enterprises Inc. is experienced with chemical etching of various metals, in a range of thicknesses. This yields a great deal of flexibility in the dimensions we can accomplish. For more information about our photo etching services or to request parts created with our unique etching process, contact us or call (866) 577-8141.