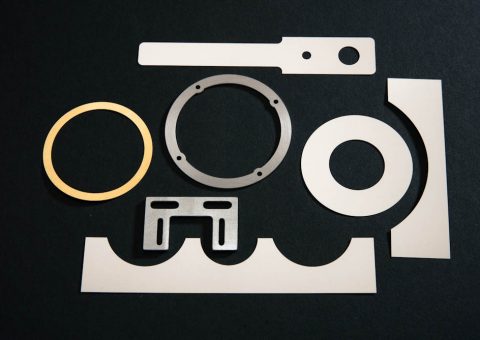

Photo Etched Metal Shims | Customized Precision Shims

A shim is a thin piece of metal that fits between two surfaces to align or otherwise adjust their fit. United Western Enterprises offers a precision etching process to create shims without burns or other deformation, as flat as possible.

We can produce a wide range of custom metal parts, thanks to an advanced and affordable photochemical etching process. It allows us to create different types of shims, including:

- Thin Shims: Parts as thin as .0003” with complex geometries can be produced without stamping or other tools.

- Single Shims: Individual orders with the raw materials of your choice, with tight tolerances for specific production processes (all requirements can be met at low costs).

- Flat Shims: Flat shims and washers (down to .001” flat) can be produced in any degree of complexity; single, laminated, and edge-bonded configurations are available.

- Custom Shims: We can manufacture shims with rectangular shapes and simple outside and inside dimensions, to complex, non-symmetrical configurations in any quantity.

Typical Applications

Shims are used in a wide range of applications, including the most advanced engineering and industrial settings. They play a critical role in various industries by enabling precision, stability, and efficiency in the manufacturing and operation of equipment. Some of the most common applications include:

Electronic Equipment

In the world of electronic equipment manufacturing, precision is key. Shims are widely employed in this industry to ensure accurate assembly and functioning of delicate electronic components. Printed circuit boards (PCBs), for instance, rely on shims to maintain proper spacing between layers, preventing short circuits and ensuring signal integrity. They are often used with printed circuit boards, to protect the CPU during heat-sink installation.

As components like microprocessors, capacitors, and resistors continue to shrink in size, the need for precise alignment becomes even more critical. Shims help achieve this alignment and, in doing so, enhance the overall performance and reliability of electronic devices.

Medical Equipment

The medical industry demands exacting precision to ensure the safety and efficacy of parts and equipment. Shims perform a vital function in this sector by ensuring optimal alignment and fit of components in devices such as MRI machines, X-ray systems, surgical instruments, and implantable medical devices. Shims help eliminate unwanted vibrations, enhance stability, and maintain the required tolerances in critical medical equipment. Moreover, the biocompatibility of shims is essential in medical applications to prevent adverse reactions within the human body.

Military and Aerospace

In the military and aerospace sectors, where equipment operates in extreme conditions and under stringent requirements, shims help to maintain reliability and safety. Aircraft, spacecraft, and military vehicles require precision alignment to ensure aerodynamic efficiency, minimize stress on structural components, and guarantee proper functionality of mechanical systems. Shims help achieve precise alignment of critical parts.

For that reason, they are used for everything from damping to integration with fuel tank and fuel injection systems. Furthermore, the use of shims allows for adjustments in equipment that may be exposed to changing conditions, like temperature variations and high G-forces.

In all these industries, shims contribute to reducing wear and tear, increasing efficiency, and minimizing the risk of malfunctions. They provide an adaptable solution for addressing small variations in alignment and spacing, which can ultimately lead to improved product quality and operational performance. As technology continues to advance, the uses of shims will likely continue to evolve, adapting to new manufacturing techniques and design requirements.

Shim Materials

Shims owe their reliability and durability to the choice of materials used in their construction. Different metals offer specific properties that make them well suited for shim manufacturing. We offer shims in many different materials, including:

Brass

This metal is a popular choice for shim production due to its excellent machinability and corrosion resistance. Composed primarily of copper and zinc, brass shims are known for their malleability, which allows them to conform to irregular surfaces. They are often used in applications where electrical conductivity is required alongside good mechanical properties. Brass shims find application in industries like electronics and telecommunications due to their electrical conductivity and non-magnetic nature.

Stainless Steel

Stainless steel shims are valued for their exceptional strength, corrosion resistance, and durability. These shims retain their properties even in harsh environments, making them excellent choices for applications that involve exposure to moisture, chemicals, and temperature variations. Stainless steel shims are often used in the aerospace, automotive, and marine industries, where reliability and resistance to wear and tear are paramount.

Aluminum

Aluminum shims offer a lightweight solution with good corrosion resistance. They are frequently used in applications where weight reduction is crucial, such as the aerospace and automotive industries. Aluminum shims are easy to fabricate and exhibit a high strength-to-weight ratio.

Beryllium Copper

These types of shims combine the unique properties of copper and beryllium to offer exceptional electrical conductivity and high tensile strength. These shims are known for their spring-like properties, which make them useful for applications requiring controlled deflection, such as pressure-sensitive devices and connectors in electronic equipment.

Phosphor Bronze

Phosphor bronze shims are valued for their corrosion resistance, electrical conductivity, and fatigue resistance. The addition of phosphorus to bronze enhances its properties, which is important for applications where repeated flexing and stress are involved. Phosphor bronze shims are commonly used in industries such as the automotive, electronics, and telecommunications sectors.

In selecting the appropriate metal for shim manufacturing, it’s important to consider factors such as the application’s environment, load-bearing requirements, and desired properties like conductivity, machinability, and resistance to various stressors. By carefully choosing the right type of metal, companies can ensure that their shims contribute to the overall performance and longevity of their equipment and devices.

Contact United Western Enterprises

United Western Enterprises uses photochemical etching to create shims with tight tolerances, intricate patterns, and minimal material distortion. The process ensures consistent quality, so it’s optimal for industries requiring fine-tuned components like electronics, medical equipment, and aerospace. To learn more or place an order for custom shims, call (800) 964-6461 or request a quote today.