Why Manufacturers Invest in Photo Etching to Make Small Metal Parts

March 2022

Photo etching, also known as photochemical machining (PCM) and photochemical milling, is a process used to to create thin metal parts using etchants and a photoresist that corrosively machines away designated areas. PCM, emerged as an offshoot of the printed circuit board arena in the 1960s, and today the best photo etching services are used by manufacturers in a wide range of industries that span automotive to aerospace, and medical to electronics and the military. Photo etching offers a variety of benefits, and this article will cover some of them with the goal to help educate manufacturing managers who are new to their role, and who are starting to learn about the various manufacturing solutions out there for creating thin metal parts.

Photo Etching can be Performed on an Extensive Range of Metals

One of the clear benefits of photo etching is that it can be performed on a wide variety of metal types. This is advantageous because it gives manufacturers and their design teams more options, and this includes the ability to use multiple metals in a single product, whether it is a prototype or one of many in a rapid production order. The most used metals that United Western Enterprises uses for photo etching services includes:

- Copper alloys

- Phosphor bronze

- Nickel silver

- Brass

- Nickel alloys

- Beryllium copper

- Nickel

- Titanium

- Steel

- Aluminum

- Stainless steel alloys

Certain products going through the manufacturing process can require multiple thin metal parts all made from different materials, and then there are products that require parts that can stand up to certain environmental conditions. That said, photo etching gives organizations the freedom to be selective with materials, and as a result products can be cheaper to produce, beat competitor products to market, and deliver a better user experience thanks to greater capabilities.

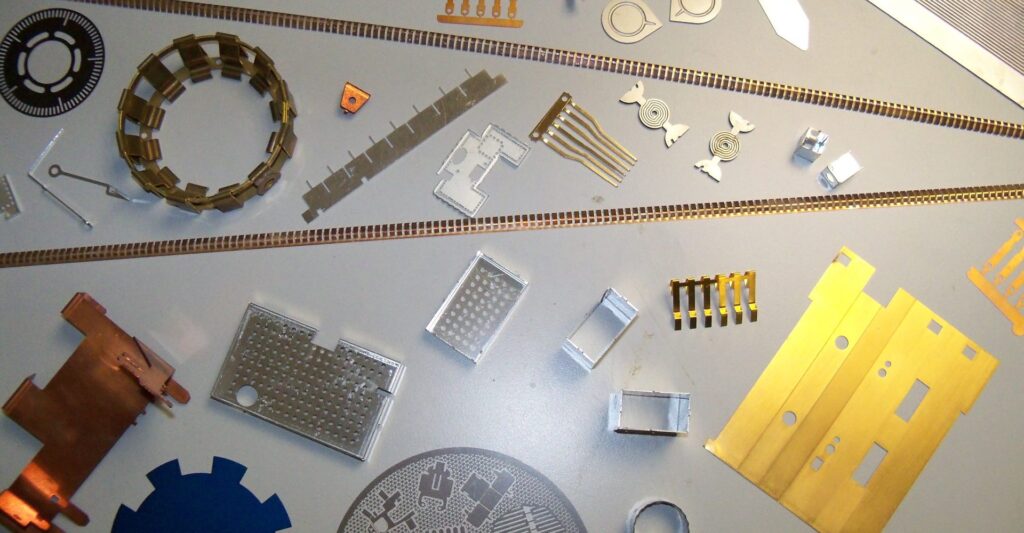

Photo Etching Can be Used to Create a Wide Range of Parts

It often saves organizations money and time when they can use the same production method to manufacture multiple part types. Photo etching services at United Western Enterprises are commonly used to create the following type of parts:

- Gaskets

- Seals

- Fine screens

- Meshes

- Springs

- Sensors

- Heat sinks

- Flexible heating elements

- Circuit components

- Jewelry

- Electrical contacts

- EMI shields

- RFI shields

In addition to being a compatible process for a wide variety of metal types, photo etching is also ideal for projects that require a multitude of fine metal part types. For organizations making devices that, for example, require sensors, RFI shields, and gaskets, going to a single manufacturer for photo etching will enable short turnaround times, and save companies a great deal of their budget while offering complete convenience.

Photo Etching Offers Design Flexibility

In addition to being extremely precise, photo etching is also more flexible than many tooling options. While expensive tooling options are required for many projects requiring last-minute changes, design flexibility is by far greater with photo etching. In addition, companies aren’t likely going to experience an increase in lead time when last minute design changes are made when photo etching services are being performed.

Manufacturers Deal with Fewer Flaws when using Photo Etching

Several other metal cutting and stamping methods can leave behind flaws that are costly and time-consuming to correct. For example, stamping can leave burrs along metal edges that need to be removed in an entirely different step in the manufacturing process. Photo etching will never leave burrs and offers a clean finish, which eliminates the need for another step, man hours, and cost is saved upfront.

The Benefits of Photo Etching are Obvious

When organizations meet with a photo etching specialist, they will see how the thin metal parts manufacturing process is precise, fast, flexible, low cost, burr-free and stress-free. Therefore, it is used in such a wide range of applications, across an expansive field of industries.

Call United Western Enterprises for a Quote on Photo Etching Services Today

Now is the time to save your organization time, money, and manpower; United Western Enterprises has decades of experience in helping organizations get their products to market quickly, with the production of flawless thin metal parts for a wide range of devices produced in record time. Whether you manufacture cell phones, stereos, cameras, or jet components, we can work with your team to create one-off conceptual pieces, to the rapid prototyping of thousands of parts, while ensuring all custom thin metal parts are flawless and consistent. Call today to learn more about the value of partnering with United Western Enterprises for the photo etching of thin metal parts today.